As your Electrical Solution Provider, Concept Sales and their manufacturers can assist with your needs in the Food & Beverage Manufacturing Industry.

Electrical work at food processing plants involves several critical tasks to ensure safety, efficiency, and compliance with stringent health regulations.

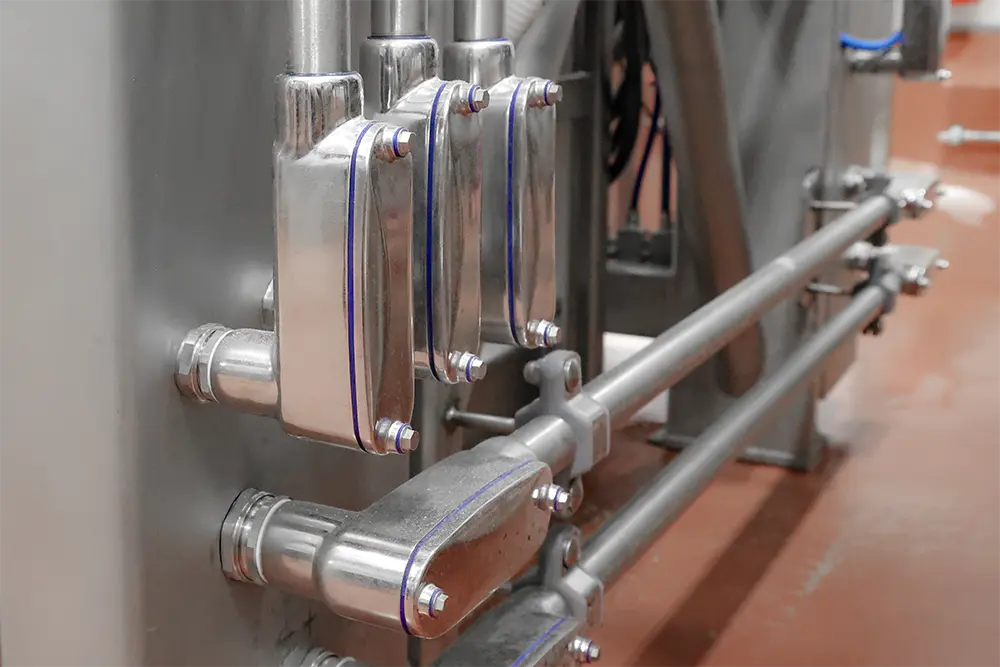

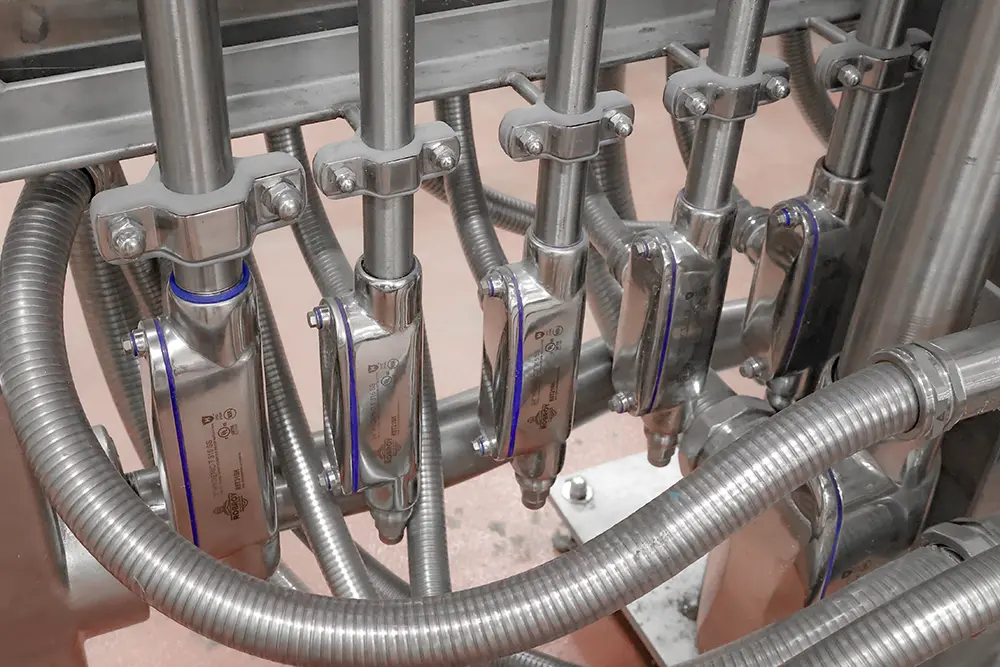

Wiring and Conduit

Food processing plants require extensive electrical wiring, which must be safely routed within several different types of conduit raceways. This protects power and data cables from damage and prevents contact with processing equipment.

Safety and Hygiene

Electrical systems must be designed to inhibit bacterial growth and prevent contamination. This often involves using food-grade materials and antimicrobial additives in conduits.

Maintenance and Testing

Electricians in this field must regularly test and maintain electrical machinery and components, which are often subjected to harsh conditions.

Compliance with Standards

Electrical installations must comply with various safety standards to ensure they do not pose any risk to food safety. This includes using materials and designs that meet FDA and other regulatory requirements.

Automation and Control Systems

Modern food processing plants rely heavily on automation. Electrical engineers design and maintain control systems that manage everything from conveyor belts to packaging machines.

Concept Sales represents these well-known electrical manufacturers, whose products and services are essential to efficient operations in the food & beverage industry: